Our Solutions

When using BDM VROC, no-code AI predictive maintenance software,

operators benefit from the following advanced insights:

Our Solutions

When using BDM VROC, no-code AI predictive maintenance software,

operators benefit from the following advanced insights:

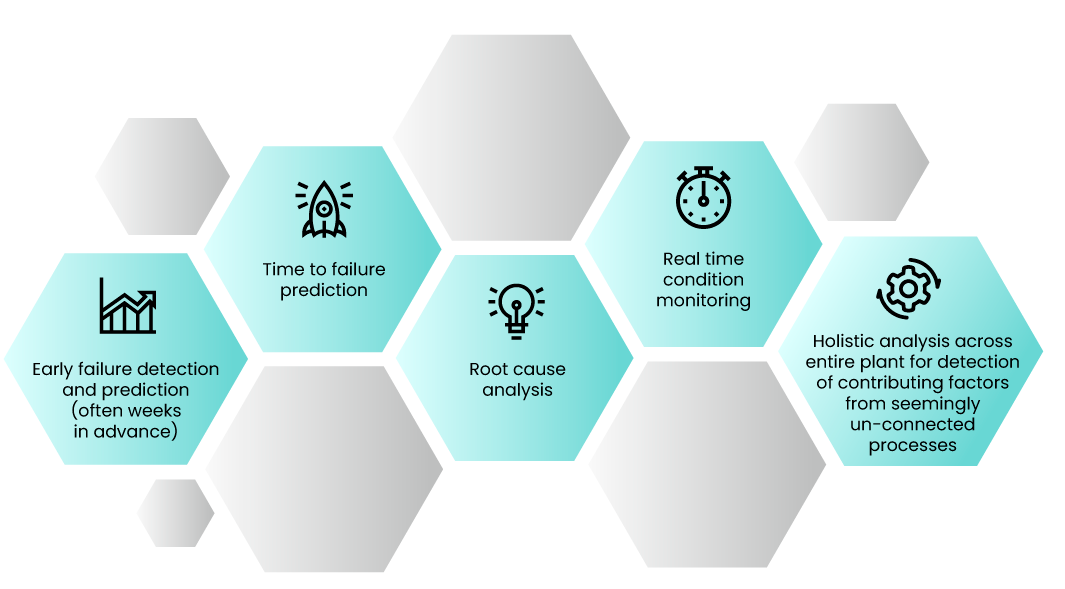

BDM – VROC’s machine learning-based predictive maintenance platform, uses sensor data and machine learning to detect anomalies and predict failures ahead of time – without the high false positives common with threshold-based predictive maintenance. As most anomalies experience unexpected failure patterns, the BDM VROC AI has been uniquely designed to continuously learn from historical and live data to predict future performance. When using BDM VROC, no-code AI predictive maintenance software, operators benefit from the following advanced insights:

Enquiry Form

Thank you for your interest in our services. If you have any questions or concerns, please fill out the form below and we will get back to you as soon as possible.