Collect. Connect. Convert.

Harnessing The Power Of Your Data Through explore the creation our AI repository for high quality information

Bumi Data Mining is the exclusive partner of VROC AI: a Software as a Service (SaaS) Platfom as a Service (PaaS) Automated Machine Learning (AutoML) platform, specifically designed and built for Industrial Big Data. BDM VROC AI is built to seamlessly integrate with your existing infrastructure and used by your existing team to quickly build, train, and maintain models of your asset without programming or coding experience.

Collect. Connect. Convert.

Harnessing The Power Of Your Data Through explore the creation our AI repository for high quality information

Bumi Data Mining is the exclusive partner of VROC AI: a Software as a Service (SaaS) Platfom as a Service (PaaS) Automated Machine Learning (AutoML) platform, specifically designed and built for Industrial Big Data. BDM VROC AI is built to seamlessly integrate with your existing infrastructure and used by your existing team to quickly build, train, and maintain models of your asset without programming or coding experience.

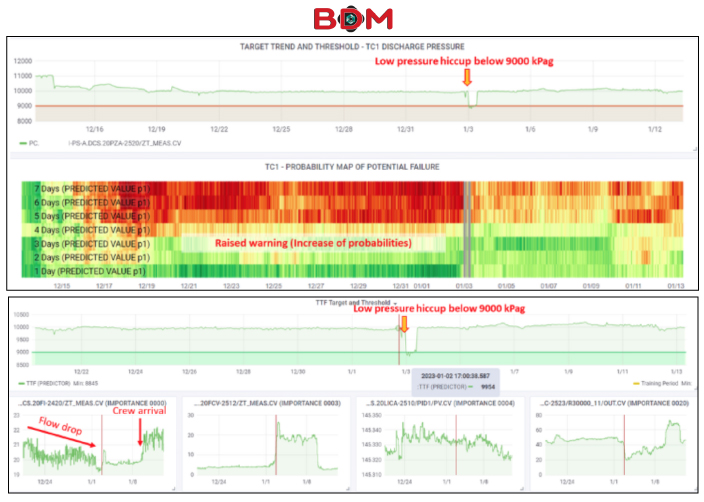

Predictive Maintenance detects flow deficiency on Turbine Compressor

BDM VROC AI predictive maintenance on O&G Turbine Compressor detects flow deficiency and predicts time to failure. Operator avoids compressor trip.

- One of BDM’s clients is an Oil and Gas operator. Their offshore platform is equipped with two primary Turbine Compressors operating in parallel. The client wanted to predict potential undesirable performance, so that they could intervene early to avoid shutdowns.

- The offshore platform is actively using BDM VROC’s no-code AI Platform. Historical data has been ingested into the platform, and live operational data is continuously ingested, this way any models created use live data to predict future outcomes.

- A Time-to-Failure (TTF) model was trained in order to predict potential Turbine Compressors (TC) undesirable performance by using TC discharge pressure when it reduces below than 9000 kPag (pre-alarm). However, the actual trip limit for pressure low low is at 5500 kPag.

- The Time to Failure (TTF) model, which was trained by incorporating historical data, warned the operation team of the increase of undesirable performance probabilities, prior to a hiccup. Multiple wells tripped at the client’s remote platforms, these were identified as the main root cause of the issue, causing low gas flowrate to compressors. Due to the monsoon season and difficulties of dispatching crew onboard to the remote platform, the low flow issue remain unsolved until the crew landed onboard and flowed back the wells.

- Sharing the TTF trending, the offshore team was able to closely monitor the ASV Opening, Compressor discharge control valve PCV Opening, and gas flowrate trending, to avoid a Turbine Compressor trip on low gas flowrate.