Collect. Connect. Convert.

Harnessing The Power Of Your Data Through explore the creation our AI repository for high quality information

Bumi Data Mining is the exclusive partner of VROC AI: a Software as a Service (SaaS) Platfom as a Service (PaaS) Automated Machine Learning (AutoML) platform, specifically designed and built for Industrial Big Data. BDM VROC AI is built to seamlessly integrate with your existing infrastructure and used by your existing team to quickly build, train, and maintain models of your asset without programming or coding experience.

Collect. Connect. Convert.

Harnessing The Power Of Your Data Through explore the creation our AI repository for high quality information

Bumi Data Mining is the exclusive partner of VROC AI: a Software as a Service (SaaS) Platfom as a Service (PaaS) Automated Machine Learning (AutoML) platform, specifically designed and built for Industrial Big Data. BDM VROC AI is built to seamlessly integrate with your existing infrastructure and used by your existing team to quickly build, train, and maintain models of your asset without programming or coding experience.

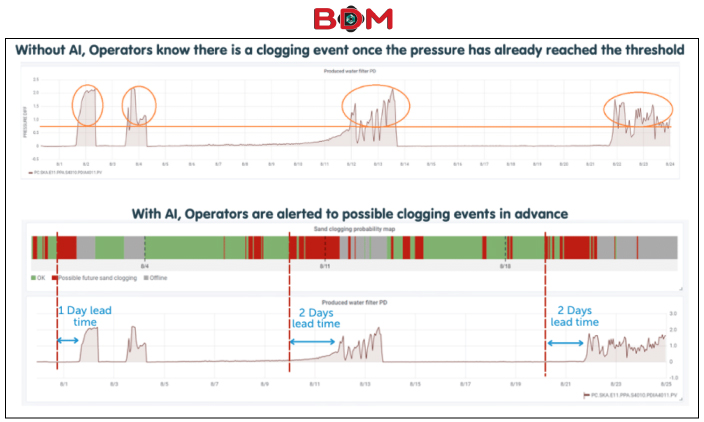

AI Predicts Produced Water Filter Clogging

Successful time to failure prediction of Oil and Gas Platform’s, Produced Water Filter

Benefits at a glance

- Successful AI prediction, with two days lead time to events

- Client can reduce manhours required to perform frequent filter change outs

- Client can avoid well deferment and production delays from unplanned events

- BDM’s customer, an offshore oil and gas platform in South East Asia recently implemented the BDM VROC AI. During the initial team training, the Operation Supervisor framed a challenge that was occurring on the platform, wanting to explore if AI could help predict the events.

- The Produced Water Filter (40microns) located downstream of the skimmer, was frequently clogging due to sand production. The event had occurred at an average of five times per month. The sanding clogging events caused well deferment, along with an increase to manhours to repeatedly change out filters, which under normal operation are changed out every two months. The events also have resulted in a decrease of the filter inventory on site.

- As a critical gas hub, this platform has been prioritised for the deployment of AI, as it has real time data availability and some pre-existing challenges.

- BDM -VROC trained a Time to Failure AI model to learn the patterns and other parameters that lead to the clogging event, so that it can predict in advance the events, and disruptions can be avoided.

- The model was trained on the last few months of historical data where the filter was frequently clogged, and the model was put into production at the end of July 2022. Previously the team had no lead time to clogging events. The initial goal was to predict the events 24 hours in advance.

- An AI model was trained to learn underlying patterns leading to each sand clogging event by using some of the available subsea parameters. The model calculates the probability of an event occurring in the future at each point in time.

- The models are continually retrained with new data to learn new behaviours and patterns so that the accuracy can continue to improve, and the lead time can be extended.

- This is a great example of using operational data and AI to assist with day-to-day operational challenges, helping to optimize production.